Akuakare – Leading Aquaculture Engineering & Cage Manufacturing Brand in Türkiye

Akuakare is one of the leading aquaculture engineering and cage manufacturing brands in Türkiye.

We design and produce HDPE fish farming cages up to 70 meters in diameter, meeting international standards for durability and reliability.

HDPE pipes resistant to UV radiation and marine conditions.

HDPE pipes resistant to UV radiation and marine conditions.- Rotomolded and injection-molded brackets manufactured in our own production facility.

- Professional teams with many years of on-site experience.

Akuakare cages have been successfully used for years in lakes, the Mediterranean and Aegean Seas, and in ocean regions such as Malaysia and India.

With their robust structure, long service life, and easy maintenance features, they have become the preferred choice of fish farmers around the world.

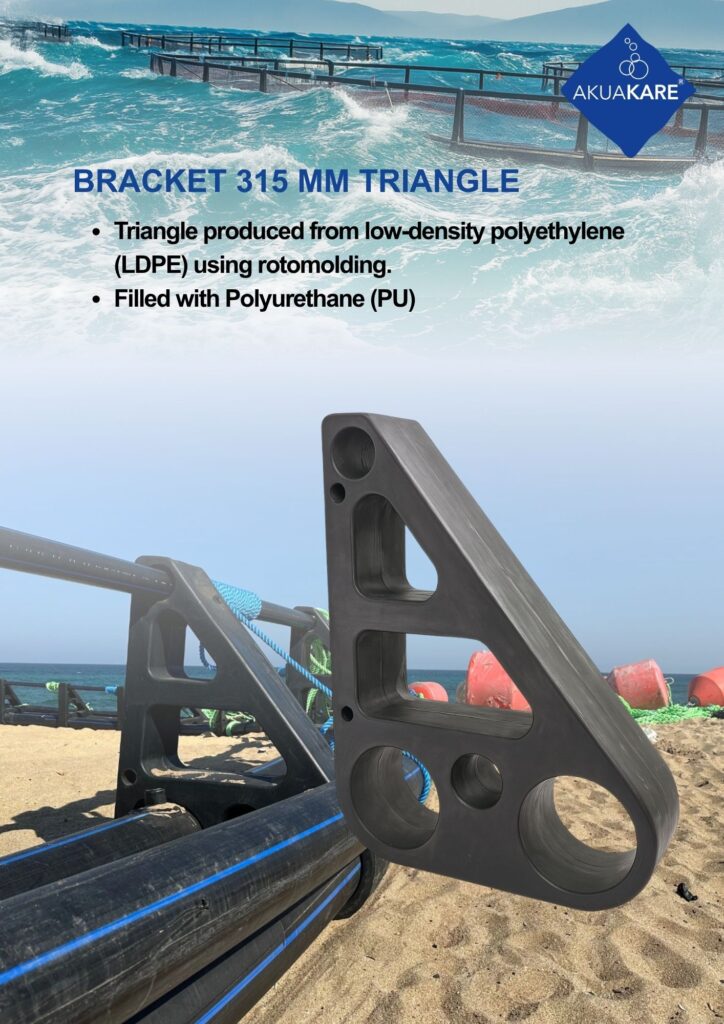

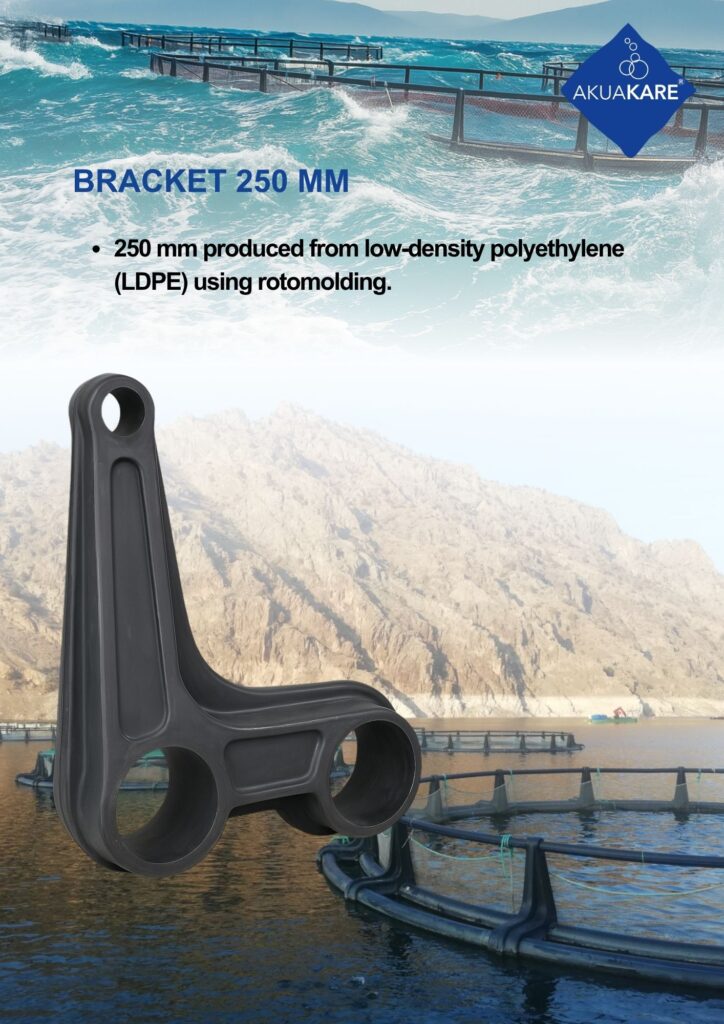

Akuakare manufactures cage brackets suitable for different pipe diameters and various sea conditions.

All brackets are made of polyethylene raw material, produced by rotational molding or injection molding, providing high strength, UV resistance, and long life in marine environments.

Our standard models include:

- L-type brackets: for pipe systems of 200, 225, 250, 315, and 400 mm diameters

- Triangle bracket model: for 315 mm pipe systems

- Injection models: for pipe systems of 250 mm, 315 mm, 400 mm, 450 mm, and 500 mm diameters

All production and quality tests are carried out in Akuakare’s own manufacturing facilities, ensuring consistent quality and reliability in every part.